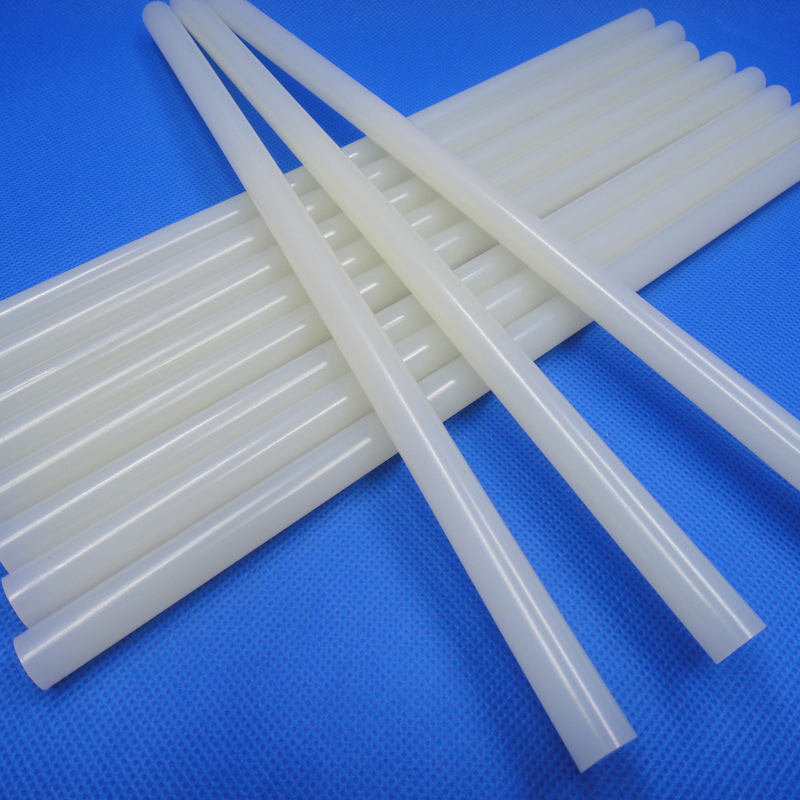

White Hot Melt Glue Sticks are thermoplastic polymers that, when heated to a specific temperature, melt quickly and exhibit excellent fluidity, enabling them to bond a variety of materials. Upon cooling, these glue sticks rapidly solidify, forming a strong bond. They are widely used in industry and everyday life. Their primary ingredients, including a polymer matrix, tackifier, and plasticizer, contribute to their excellent bonding properties and stability. During production, strict adherence to industry standards ensures the optimal quality and performance of each glue stick.

| Model | HCGG777 |

| Viscosity (170º) | 3800 ± 200 CPS |

| Softening Time | 86 ± 5℃ |

| Open Time | 6~10S |

| Set Time | 2~3S |

| Application Temperature | 160℃-190℃ |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

1. High Bond Strength:

White Hot Melt Glue Sticks offer exceptional bond strength, enabling them to securely bond a wide variety of materials. Their bond strength leads the industry standard and can withstand significant tensile and shear forces. In testing, their bond strength has been shown to be significantly higher than that of standard hot melt adhesives. This ensures reliable bonding in a wide range of applications, ensuring a secure bond between lightweight and heavy materials.

2. Fast Curing:

White Hot Melt Glue Sticks cure extremely quickly, enabling them to bond quickly. With a setting time of 2-3 seconds, the glue only needs a short cooling period after melting to form a strong bond. This rapid curing significantly improves work efficiency, particularly in industrial production, significantly shortening production cycles and increasing productivity. Furthermore, the fast curing time reduces the inconvenience of waiting for curing to occur, making operation more convenient.

3. Excellent Flowability:

White Hot Melt Glue Sticks exhibit excellent flowability when heated to 170°C, with a viscosity of 3800 ± 200 CPS. This moderate viscosity allows the stick to flow smoothly through the glue gun without clogging or unevenness. This excellent flowability not only improves the glue's application efficiency but also ensures even application to the bonding surface, resulting in a superior bond. This makes it easy to bond complex shapes and large surfaces.

4. Wide Temperature Range:

White Hot Melt Glue Sticks have an application temperature range of 160°C-190°C, making them suitable for use in a variety of environmental conditions. They maintain stable performance in both cold winters and scorching summers. This wide temperature range makes them suitable for a variety of industrial and residential applications, providing reliable bonding results both indoors and outdoors. Furthermore, they maintain excellent bonding performance on a variety of surfaces, unaffected by temperature fluctuations.

5. Precise Softening Time:

White Hot Melt Glue Sticks have a softening time of 86 ± 5°C. This precise softening time ensures uniform melting during heating. In practice, this means users can precisely control the heating time and temperature to achieve optimal bonding results. This precise softening time not only improves operational control but also prevents bonding failures caused by overheating or underheating, ensuring ideal results every time.

6. Optimal Open Time:

White Hot Melt Glue Sticks have an open time of 6-10 seconds, ensuring ample working time without degrading the adhesive's performance due to extended open times. Users can complete bonding operations within this timeframe, ensuring even application of the adhesive to the bonding surface. This optimal open time not only enhances operational flexibility but also ensures consistent bonding results, providing a superior experience in both manual and automated production.

1. Packaging Industry:

In the packaging industry, White Hot Melt Glue Sticks are an ideal adhesive. They quickly bond packaging materials such as cartons and cartons, ensuring secure and stable packaging. Their fast curing and high bond strength make the packaging process more efficient and significantly shorten production cycles. They also maintain excellent adhesion to a variety of packaging materials, from paper to plastic, providing a reliable bonding solution for the packaging industry.

2. Woodworking:

In the woodworking industry, White Hot Melt Glue Sticks securely bond wood and wood products. Their excellent bond strength and fast curing make the woodworking process more efficient. In applications such as furniture manufacturing and wooden door installation, they quickly bond wood components, ensuring the structural stability and aesthetics of furniture. They also form a strong bond layer on the wood surface, preventing it from loosening due to moisture or external forces, providing reliable bonding support for the woodworking industry.

3. Electronics Industry:

In the electronics industry, White Hot Melt Glue Sticks can be used to secure and protect electronic components. Its excellent flowability and moderate open time allow for precise application to electronic components, ensuring secure and protective attachment. During electronic device assembly, it quickly bonds circuit boards and other components, improving production efficiency. It also forms a protective film on the surface of electronic components, preventing damage from moisture and external forces, providing a reliable bonding and protection solution for the electronics industry.

4. Automotive Manufacturing:

In the automotive industry, White Hot Melt Glue Sticks can be used to bond automotive interiors and components. Its high bond strength and fast curing properties make automotive interior assembly more efficient. When bonding interior components such as car seats and dashboards, it quickly bonds and forms a strong bond, ensuring interior stability and aesthetics. It also maintains excellent adhesion to diverse surfaces, whether plastic or metal, providing reliable bonding support for the automotive industry.

5. Daily Life:

White Hot Melt Glue Sticks have a wide range of applications in everyday life. They can be used in home renovations, crafts, and other applications. In home renovations, they quickly bond materials like tiles and wallpaper, ensuring a durable and aesthetically pleasing finish. In crafts, they can easily bond a variety of materials, including paper, wood, and plastic. Their fast curing and high bond strength make everyday bonding operations more convenient, bringing added convenience to people's lives.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

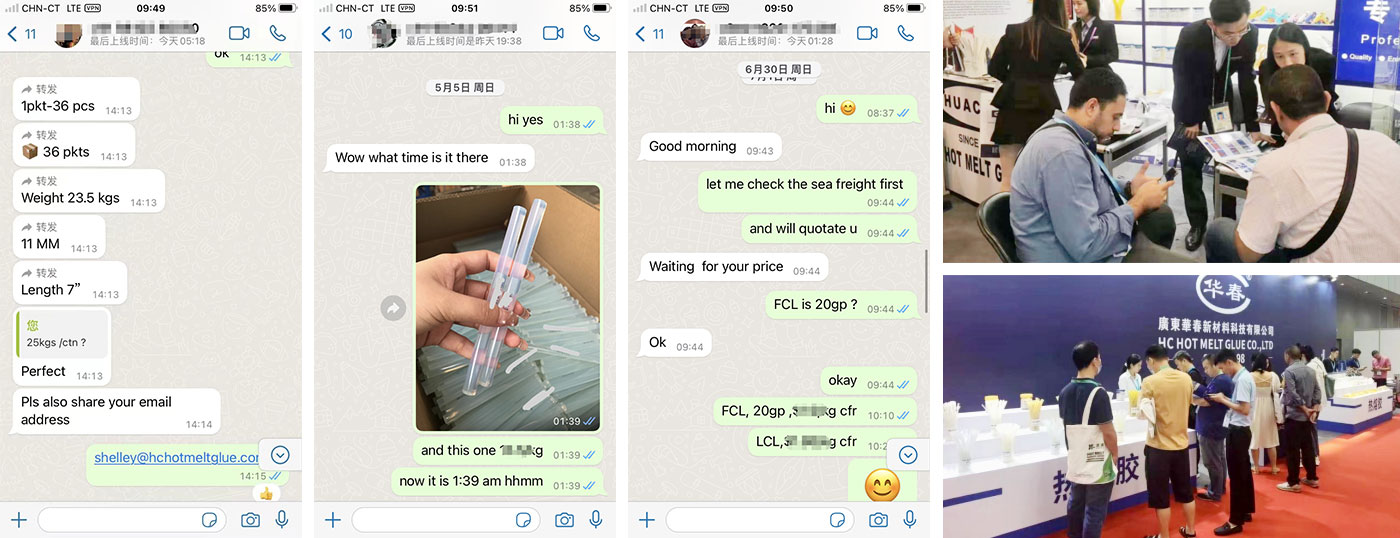

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.