Cold Resistance Hot Glue Sticks are a hot melt adhesive product that maintains excellent bonding performance in low-temperature environments. Through a special formula and process, these glue sticks prevent brittleness, cracking, or loss of adhesion in cold conditions, ensuring stable and reliable bonding. They are widely used in applications requiring low-temperature bonding and are an ideal choice for cold-weather bonding needs.

| Model | HCGG102 |

| Viscosity (170º) | 7051 ± 200 CPS |

| Softening Time | 79 ± 5℃ |

| Open Time | 32~35S |

| Set Time | 2~5S |

| Application Temperature | 160℃-190℃ |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

1. High Adhesion:

Cold Resistance Hot Glue Sticks boast excellent adhesion and high bond strength, allowing them to adhere securely to a variety of surfaces. In its molten state at 170°C, its viscosity is 7051 ± 200 CPS. This ensures even distribution and sufficient adhesion during application. Even under certain external forces, the adhesive maintains a tight bond, meeting bonding requirements in various scenarios.

2. Fast Curing:

Cold Resistance Hot Glue Sticks offer fast curing. Their rapid curing time, from melt to initial curing, is only 2-5 seconds, significantly improving work efficiency. This rapid curing allows for rapid bonding operations on the production line, reducing waiting time and increasing production efficiency. They are particularly suitable for products that require rapid assembly, such as bonding electronic device components.

3. High Temperature Resistance:

Cold Resistance Hot Glue Sticks maintain stable performance over a wide temperature range. Its softening time is 79 ± 5°C, meaning the adhesive begins to soften near 80°C and remains firm at room temperature. Furthermore, its applicable temperature range is 160-190°C. After melting at high temperatures, it quickly cools and solidifies, maintaining excellent bonding performance even in cold environments, making it suitable for applications with large temperature differences.

4. High Transparency:

Cold Resistance Hot Glue Sticks are transparent, ensuring they adhere seamlessly to the surface. For aesthetically pleasing products, such as crafts and decorative items, the transparent adhesive effectively conceals adhesive marks, enhancing the overall quality and adding a clean, polished look.

5. Easy Operation:

Cold Resistance Hot Glue Sticks are extremely easy to use. Their open time is 32-35 seconds, providing ample time for operator adjustment and ensuring a precise bond. To use, simply place the glue stick into the hot melt glue gun and heat it to the appropriate temperature. There's no need for complicated mixing or pretreatment, making it easy to use and suitable for operators of all skill levels.

6. High Cold Resistance:

Cold Resistance Hot Glue Sticks remain flexible at -30°C and pass ASTM D746 low-temperature impact testing with no cracks in the adhesive layer. Their glass transition temperature (Tg) is as low as -45°C, far exceeding that of ordinary EVA glue sticks (Tg ≥ -20°C).

7. High Aging Resistance:

Cold Resistance Hot Glue Sticks exhibit excellent aging resistance. Over long-term use, they resist the effects of environmental factors such as UV rays and oxygen, and are not susceptible to yellowing, embrittlement, and other aging phenomena. Their bond strength and performance remain stable over time, extending the product's lifespan and reducing the risk of bond failure due to adhesive aging.

8. High Compatibility:

Cold Resistance Hot Glue Sticks are compatible with a variety of materials. Cold Resistance Hot Glue Sticks form strong bonds with common materials, including plastic, metal, wood, and glass. This broad compatibility allows them to meet bonding requirements for a wide range of material combinations, facilitating diverse product designs and reducing bonding difficulties caused by material differences.

1. Cold Chain Logistics Packaging:

Transparent Cold Resistance Hot Glue Sticks demonstrate exceptional performance in cold chain logistics, particularly for food and pharmaceutical packaging requiring long-term low-temperature storage. They maintain stable bond strength in extreme low-temperature environments ranging from -30°C to -40°C, fully meeting international cold chain transportation standards (such as ISTA 3E). Their unique molecular structure effectively resists condensation, ensuring a tight seal. In packaging applications such as seafood and frozen foods, the adhesive layer maintains a peel strength exceeding 3.8 N/cm (ASTM D903 test standard) after repeated freeze-thaw cycles, significantly exceeding that of conventional hot melt adhesives. They also comply with FDA 21CFR 175.300 for food contact materials.

2. Automotive Interior Fixing:

In the automotive industry, Cold Resistance Hot Glue Sticks are primarily used for bonding interior components such as door panels, headliners, and instrument panels. Passing the ISO 16750-4 automotive electronics low-temperature testing standard, it maintains excellent flexibility and impact resistance (impact strength ≥ 15 kJ/m²) even at -40°C. It is particularly suitable for insulating and securing battery packs in new energy electric vehicles, and its UL94 V-0 flame retardancy rating effectively enhances safety. After 500 hours of SAE J2380 vibration testing, the bond showed no loosening or cracking, fully meeting the automotive industry's TS16949 quality management system requirements.

3. Precision Electronic Component Encapsulation:

This Cold Resistance Hot Glue Stick demonstrates excellent performance for electronic products operating in low-temperature environments. Its application temperature range of 160-190°C prevents damage to sensitive electronic components, and its cured dielectric strength reaches 15 kV/mm (IEC 60243 standard). It is particularly suitable for securing components on PCBs used in outdoor electronic equipment in cold regions, such as surveillance cameras and communication base stations. It maintains stable insulation performance (volume resistivity > 10¹⁵Ω·cm) even at -30°C. Passing MSL Level 3 moisture sensitivity testing ensures the long-term reliability of electronic products.

4. Outdoor Sports Equipment Manufacturing:

Cold Resistance Hot Glue Sticks excel in the manufacturing of outdoor sports equipment such as skis and trekking poles. Passing the EN 12365-2 low-temperature flex test (1,000 flex cycles at -40°C without cracking), its unique flexible formula ensures the structural integrity of equipment in extreme environments. When used for bonding sports footwear, it passes the SATRA TM144 low-temperature folding test (50,000 folds at -25°C) with a peel strength retention rate exceeding 85%. It also complies with EU REACH regulations and contains no hazardous substances.

5. Medical Low-Temperature Storage Systems:

In the medical field, this product is designed for the low-temperature storage needs of vaccines, biologics, and other products. Passing ISO 10993-5 cytotoxicity testing and USP Class VI biocompatibility certification, it ensures safety in direct contact with pharmaceuticals. Bond strength retention exceeds 90% at 4°C and does not crack when stored at -70°C. It is particularly suitable for attaching labels to ampoules in automated filling systems. It maintains adhesion even after short-term exposure to liquid nitrogen (-196°C), fully meeting GMP cleanroom production standards.

6. Specialty Textile Composites:

In the manufacturing of functional clothing, these Transparent Cold Resistance Hot Glue Sticks are used for laminating windproof and waterproof fabrics. They have passed the AATCC 135 low-temperature water wash test (50 washes at -30°C) and demonstrate a peel strength of >3.5N/cm. Their microporous structure (pore size 20-50μm) ensures strong bonding while maintaining excellent moisture permeability (MVTR >5000g/m²/24h). They are particularly suitable for the manufacture of specialized clothing such as polar expedition uniforms and mountaineering apparel. They maintain a soft touch even at -50°C, completely eliminating the problem of traditional adhesives curing at low temperatures.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

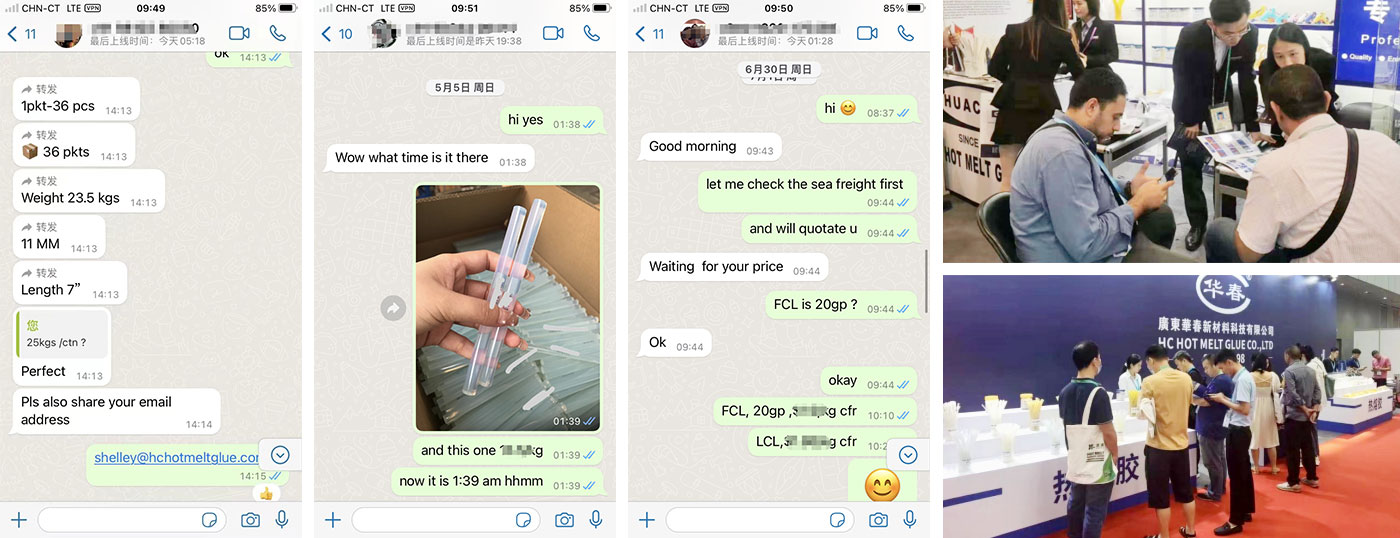

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.