Packaging Hot Melt Adhesive is a hot melt adhesive designed specifically for the packaging industry. This type of adhesive is widely used in the packaging field, mainly for bonding various packaging materials, such as cartons, paper boxes, plastic films, etc. Packaging Hot Melt Adhesive has become the preferred adhesive in the packaging industry due to its fast bonding, easy operation and high bonding strength. After being heated to a molten state, it quickly cools and forms a bond through pressure. This fast response characteristic makes it very suitable for automated production lines. The use of Packaging Hot Melt Adhesive reduces energy consumption and time in the production process and improves production efficiency. In addition, the bonding effect of this adhesive is affected by temperature, pressure and contact time, and it can usually quickly form a stable bond under appropriate conditions.

| Model | HCGGH225 |

| Viscosity (170º) | 2468 ± 200 CPS |

| Softening Time | 112 ± 5℃ |

| Open Time | 10~15S |

| Set Time | 3~5S |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

Fast bonding

Packaging Hot Melt Adhesive Pellets have excellent initial bonding strength and can form a strong bond in a very short time. This fast bonding feature is particularly suitable for high-speed production lines, greatly improving production efficiency and meeting the dual requirements of speed and efficiency in modern industrial production.

Peel strength

Packaging Hot Melt Adhesive Pellets exhibit excellent peel strength and can maintain bonding stability even when subjected to external forces. This feature makes it excellent in application scenarios that require a certain amount of tension, such as in the bonding process of packaging materials, to ensure the integrity and durability of the packaging.

Temperature resistance

Packaging Hot Melt Adhesive Pellets can still maintain excellent bonding performance in low temperature environments, while providing stable bonding effects in high temperature environments. This excellent temperature resistance enables it to adapt to various environmental conditions, thereby increasing its application flexibility and reliability.

Stable performance

The Packaging Hot Melt Adhesive Pellets exhibit excellent stability in high temperature environments, and are not easily affected by temperature fluctuations. This stability is critical for applications that require use under high temperature conditions, such as in automotive manufacturing and electronic equipment assembly, to ensure the durability and reliability of the bond.

Wide range of bonding

Packaging Hot Melt Adhesive Pellets exhibit good bonding performance on a variety of materials, including but not limited to various paper types. This wide range of bonding performance enables it to adapt to a variety of application scenarios and provides an effective solution for bonding different materials.

Easy operation

The operation process of Packaging Hot Melt Adhesive Pellets is very simple. It only needs to be heated to a molten state through a hot melt device, and then bonded by pressure. This simple operation not only reduces the difficulty of use, but also significantly improves production efficiency, making the production process smoother and more efficient.

Environmental protection and safety

Packaging Hot Melt Adhesive Pellets does not produce harmful gases during production and use, and fully meets environmental protection requirements. At the same time, it is extremely safe for the human body and the environment, effectively reducing safety risks in industrial production, and providing additional protection for workers and the environment.

Cost-effectiveness

Packaging Hot Melt Adhesive Pellets are cost-effective and can significantly reduce production costs due to their fast bonding and easy operation. At the same time, their stable performance and wide bonding properties also reduce material waste, improve economic benefits, and enable enterprises to gain greater advantages in competition.

Automated production lines

Packaging Hot Melt Adhesive Pellets are designed for automated production lines and are suitable for high-speed packaging processes. Its fast bonding characteristics allow the production line to operate continuously without waiting for a long time for the adhesive to dry, which significantly improves production efficiency. In addition, the stable performance of this adhesive ensures consistent bonding under different temperature and humidity conditions, ensuring consistent packaging quality.

Pre-coating process

This product is very suitable for pre-coating process, which can pre-coat a layer of hot melt adhesive during the paper production process. In this way, when the paper is used for packaging, it can be quickly bonded by heat and pressure, greatly simplifying the packaging process. The pre-coating process not only increases the packaging speed, but also reduces the complexity of on-site operations and reduces the requirements for operator skills.

Carton bonding

In carton manufacturing, Packaging Hot Melt Adhesive Pellets are used to bond various parts of the carton, such as the bottom, cover and sides, providing a high-strength bonding effect. The heat resistance of this adhesive ensures that the carton can maintain good structural strength under different environmental conditions, and is not easy to deform or damage, thereby improving the durability and reliability of the carton.

Carton packaging

During the carton packaging process, Packaging Hot Melt Adhesive Pellets are used for bonding of cartons to ensure the firmness and sealing of cartons. The rapid bonding characteristics of this adhesive make the production of cartons more efficient, and its good peel strength ensures that the carton is not easy to debond when subjected to external forces, ensuring the integrity and safety of the packaging.

Plastic film packaging

Packaging Hot Melt Adhesive Pellets are also suitable for plastic film packaging, providing good bonding performance to ensure the integrity of the packaging. The heat resistance of this adhesive enables plastic film packaging to maintain good bonding effects in high or low temperature environments, and is not easy to debond or crack, thereby improving the reliability and durability of the packaging.

Various paper types

This product can be used for pre-coating and bonding of various paper types, including but not limited to kraft paper, coated paper, corrugated paper, etc., to meet the bonding needs of different papers. This wide range of applicability makes Packaging Hot Melt Adhesive Pellets an ideal choice for the packaging industry, whether it is used for food packaging, gift packaging or industrial product packaging, it can provide a reliable bonding solution.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

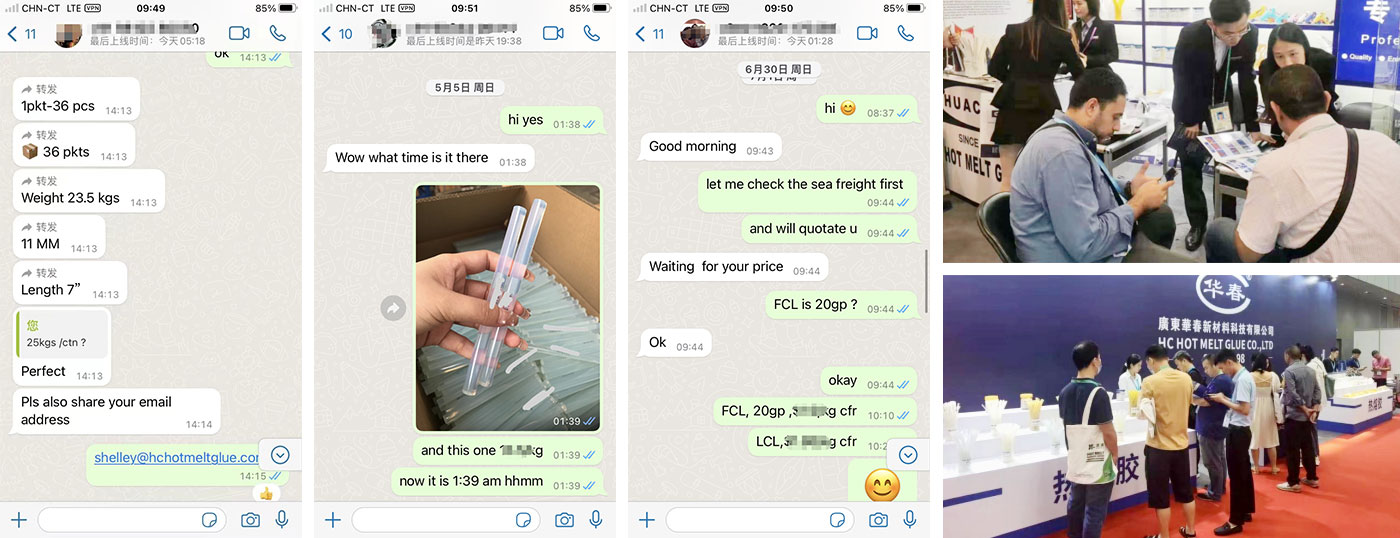

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.