Hot Melt Packaging Adhesive is a kind of adhesive that is solid at room temperature and can quickly bond materials after heating and melting. It is melted by heating equipment and then applied to the surface of the adherend, and then cooled and solidified to form a bond. Its main components include polymer matrix, tackifier, plasticizer, etc. These components work synergistically to give the adhesive good bonding properties, thermal stability and flexibility. It is widely used in the packaging industry because of its advantages such as convenient operation, fast bonding, no solvent volatilization, etc., which meets the needs of environmental protection and efficient production, and is an indispensable material for modern packaging.

| Model | HCGGH313 |

| Viscosity (170º) | 1860 ± 200 CPS |

| Softening Time | 94 ± 5℃ |

| Open Time | 28~35S |

| Set Time | 5~10S |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

1. Moderate viscosity:

The viscosity of Hot Melt Packaging Adhesive Pellets at 170℃ is 1860 ± 200 CPS, which is moderate and meets the requirements of industry standards. This viscosity range ensures that the glue particles can be evenly applied to the surface of the gift paper bag in a molten state, and it will not be difficult to apply due to too high viscosity, nor will it flow due to too low viscosity, thereby ensuring the stability and consistency of the bonding effect. In actual use, it can effectively avoid the problem of glue accumulation or uneven coating, and improve production efficiency and product quality.

2. Stable softening temperature:

The softening temperature of this Hot Melt Packaging Adhesive is 94 ± 5℃, which is in the reasonable range of industry standards. This means that in a normal production environment, the hot melt adhesive can quickly soften and reach the best bonding state within a relatively stable temperature range. The stable softening temperature helps to reduce the difference in bonding effect caused by temperature fluctuations, ensuring consistent bonding strength in different batches of production. At the same time, this temperature range is also suitable for the production process of most gift paper bags and will not cause thermal damage to the paper bag material.

3. Reasonable opening time:

The opening time of Hot Melt Packaging Adhesive Pellets is 28~35 seconds, which is in line with industry standards and provides operators with sufficient time for bonding operations. In actual applications, operators can have enough time to accurately bond the various parts of the gift paper bag together after the glue is applied, avoiding weak bonding due to too short an opening time or glue coagulation failure due to too long an opening time. Reasonable opening time helps to improve production efficiency and product quality and reduce the scrap rate caused by operating errors.

4. Fast curing speed:

The curing time is 5~10 seconds, and fast curing speed is one of the significant features of this Hot Melt Packaging Adhesive Pellets. This curing time is much lower than the industry average, and the bonding process can be completed in a short time, greatly improving production efficiency. Fast curing not only reduces production waiting time, but also ensures that the gift paper bag reaches sufficient strength in a short time, which is convenient for subsequent packaging and transportation. This feature is particularly suitable for packaging application scenarios such as gift paper bags that require rapid production and delivery.

5. Environmentally friendly and pollution-free:

Hot Melt Packaging Adhesive Pellets strictly follow environmental standards during the production process, do not contain harmful substances, and meet the environmental protection requirements of the industry. During use, hot melt adhesive will not release harmful gases or residual harmful substances, and will not pollute the environment and human health. This is especially important for products that frequently come into contact with the human body, such as gift paper bags, which can ensure the safety and environmental protection of the products and meet the needs of modern consumers for environmentally friendly products.

6. Customizable services:

Provide OEM/ODM services, and customize the formula and packaging form of Hot Melt Packaging Adhesive according to the specific needs of customers. This service model can meet the personalized needs of different customers in different application scenarios. Whether it is the size, shape or bonding requirements of gift paper bags, they can be met through customized services. Customized services not only improve the applicability of products, but also help customers stand out in market competition and increase the added value of products.

7. Good flexibility:

Hot Melt Packaging Adhesive has good flexibility and can adapt to the folding and bending of gift paper bags during use. Even in low temperature environments, hot melt adhesive will not become brittle or crack, and maintain stable bonding performance. This feature is crucial to the reliability of gift paper bags during transportation and use, and can effectively avoid packaging damage caused by adhesive layer breakage and extend the service life of the product.

8. High bonding strength:

Hot Melt Packaging Adhesive has high bonding strength, which can ensure that gift paper bags can maintain a strong bonding effect in various environments. Whether facing the squeeze of heavy objects or changes in the external environment, hot melt adhesive can provide reliable bonding support. This feature is due to its optimized formula and production process, which makes it highly competitive in the industry and can meet the high requirements of gift paper bags for bonding strength.

1. Gift paper bag sealing

During the sealing process of gift paper bags, Hot Melt Packaging Adhesive can quickly bond the opening part of the paper bag to ensure a firm seal. Its moderate viscosity and reasonable open time allow operators to easily seal the paper bag, while the fast curing speed ensures that the seal reaches sufficient strength in a short time, preventing the gifts from falling out of the paper bag during transportation and ensuring the safety of the gifts.

2. Gift paper bag decoration bonding

For decorative elements on gift paper bags, such as ribbons, labels, etc., Hot Melt Packaging Adhesive Pellets can provide reliable bonding support. Its good flexibility and high bonding strength can ensure that the decorative elements are firmly adhered to the surface of the paper bag, and will not fall off even when the paper bag is folded or squeezed, maintaining the beauty of the gift paper bag and improving the overall quality of the product.

3. Gift paper bag internal structure bonding

In the bonding of the internal structure of gift paper bags, such as interlayers, support plates, etc., this Hot Melt Packaging Adhesive Pellets can play an important role. Its fast curing and high bonding strength characteristics can ensure the stability of the internal structure, prevent the paper bag from deformation or damage during use, thereby extending the service life of the gift paper bag and improving the practicality of the product.

4. Gift paper bag combination packaging

When multiple gift paper bags need to be combined and packaged, this Hot Melt Packaging Adhesive can firmly bond the individual paper bags together to form a whole. Its stable bonding performance and fast curing speed can ensure the firmness and stability of the combined packaging, which is convenient for transportation and storage, and can also improve the overall appearance of the product and enhance the attractiveness of the product.

5. Special shape bonding of gift paper bags

For some gift paper bags with special shapes, such as three-dimensional shapes, multi-layer structures, etc., this Hot Melt Packaging Adhesive can meet complex bonding requirements. Its good flexibility and moderate viscosity can adapt to the bonding requirements of different shapes and angles, ensuring that the gift paper bags with special shapes can remain stable during the production process, and finally present a beautiful appearance effect to meet the needs of high-end gift packaging.

6. Rework and repair of gift paper bags

During the production process of gift paper bags, if poor bonding or other problems occur and need to be reworked and repaired, Hot Melt Packaging Adhesive can provide an effective solution. Its good flexibility and repeatable bonding performance allow operators to easily re-bond the wrong part without damaging the paper bag, thereby reducing the scrap rate, reducing production costs and improving production efficiency.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

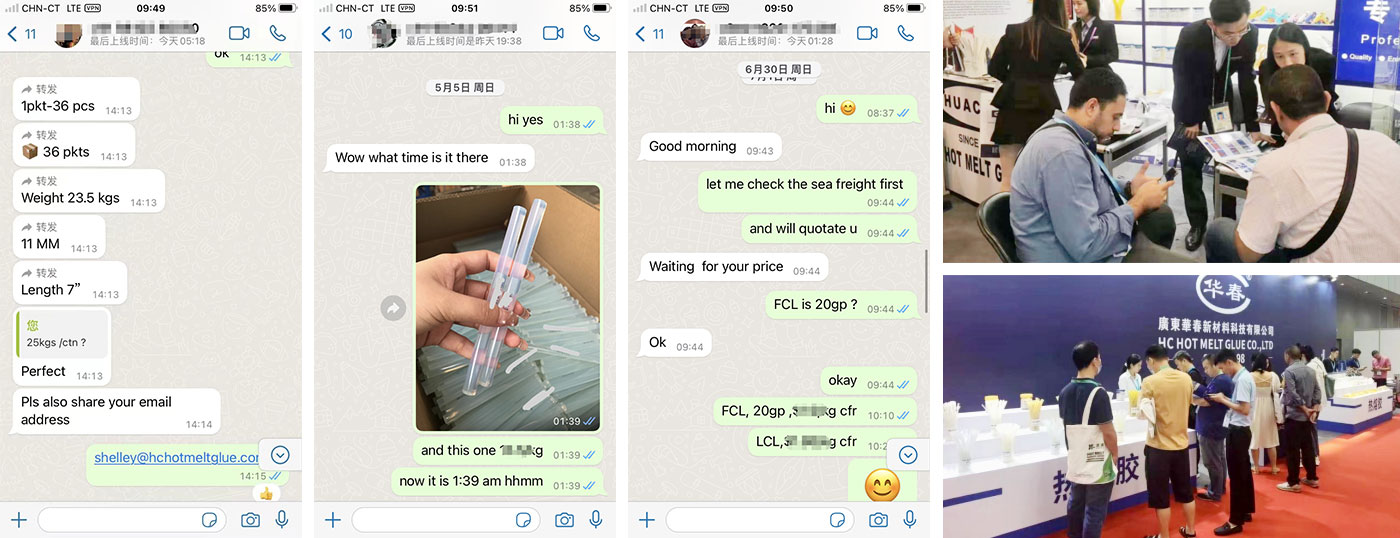

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.