Hot Melt Extrusion Pellets are a solid adhesive material made from thermoplastic polymers. After being heated and melted, this product can quickly solidify during the cooling process of the bonded surface to form a high-strength bond. The curing process does not require the participation of moisture or chemical reactions, and relies entirely on physical cooling to ensure high bonding efficiency and is not affected by environmental humidity. . Hot melt adhesive extrusion pellets are usually made of ethylene-vinyl acetate copolymer (EVA), polyolefins, tackifying resins, waxes and antioxidants through high-temperature mixing, extrusion, cooling, pelletizing and other processes.

| Model | HCGGH313 |

| Viscosity (170º) | 1860 ± 200 CPS |

| Softening Time | 94 ± 5℃ |

| Open Time | 28~35S |

| Set Time | 5~10S |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

1. Environmental protection and safety:

Hot Melt Extrusion Pellets do not contain any solvents, heavy metals or harmful volatile substances, and comply with international environmental standards such as RoHS and REACH. There is no odor or pollution during production and use, which is friendly to the human body and the environment and supports the concept of sustainable development. At the same time, its solid form reduces safety hazards in transportation and storage, making it easier for companies to build a green supply chain system.

2. High bonding strength:

Hot Melt Extrusion Pellets have excellent initial adhesion and final bonding strength, and can form a strong bond between a variety of paper materials. Its molecular structure design is optimized to improve the adhesion to low surface energy materials and ensure long-lasting and stable bonding effect. At the same time, the internal cross-linking density of the colloid is moderate, which not only ensures the bonding strength, but also does not affect the flexibility due to excessive hardening, and performs well in application scenarios such as paper bags and gift boxes.

3. Good fluidity:

The particles show good flow properties in the molten state and are easy to be evenly coated on the bonding surface through the extrusion equipment. Its low melt viscosity characteristics help to improve the coating accuracy and coverage area, and adapt to the continuous operation requirements of high-speed automated equipment. At the same time, good fluidity also helps to fill small gaps, improve the overall tightness of the bonding interface, and enhance the sealing and structural stability.

4. Strong thermal stability:

Hot Melt Extrusion Pellets are specially formulated to have good thermal stability and are not easy to decompose or discolor during high-temperature processing. Long-term heating can still maintain the original bonding performance, reducing the risk of equipment clogging and glue deterioration. Its heat resistance also makes it suitable for production lines that run for a long time, avoiding frequent replacement of glue, reducing the frequency of downtime maintenance, and improving overall production efficiency.

5. Cost control advantage:

Compared with traditional glue, hot melt adhesive particles are more economical in unit dosage and do not require additional drying time. Its efficient bonding performance combined with high-speed production lines helps to reduce overall costs and enhance corporate competitiveness. At the same time, its long shelf life and stable process performance also help to reduce scrap and rework rates, further optimizing the input-output ratio of production.

6. Easy to store and transport:

Hot melt adhesive particles are packaged in dry and sealed packaging with good moisture-proof properties. They will not deteriorate during long-term storage at room temperature, and are not easy to break or agglomerate during transportation, which is convenient for factory batch procurement and inventory management. In addition, the particles are regular in shape, which is convenient for automatic feeding system to identify and transport, reduce manual intervention, and improve the level of production automation.

7. Strong processing adaptability:

The particles are uniform in size and have good fluidity, which is suitable for the feeding system of various brands of fully automatic packaging equipment. Its physical properties are stable, and there will be no problems with unstable feeding or nozzle clogging due to equipment differences, which improves overall production efficiency. At the same time, the product can maintain good operability in different temperature ranges and meet the bonding needs under diverse process conditions.

1. Gift paper bag packaging

Hot Melt Extrusion Pellets are specially designed for the automatic bottom sealing and side bonding process of gift paper bags, and are suitable for the production of paper bags of various thicknesses and materials. Its quick-drying characteristics can effectively improve the sealing efficiency, while ensuring the neat appearance and stable structure of the finished bag. During the high-speed lamination process, the hot melt adhesive particles can achieve seamless connection, prevent cracking or degumming, and improve the aesthetics and practicality of the end product.

2. Automatic paper box bonding

It is suitable for the edge bonding, bottom folding bonding and other process flows of fully automatic paper box forming machines. Hot Melt Extrusion Pellets can provide stable bonding force under high-speed operation conditions to ensure that the paper box is not easy to crack during transportation and use. Its excellent wettability enables the colloid to quickly penetrate into the paper fiber to form a strong bonding layer, which improves the load-bearing capacity and pressure resistance of the finished paper box.

3. Semi-automatic packaging line matching

This product is compatible with semi-automatic packaging equipment, such as manually assisted paper box assembly machines, clamshell laminating machines, etc. It is easy to operate and has a fast curing speed. It is suitable for small and medium-sized enterprises to improve efficiency while controlling investment costs. Even when the operation of personnel is not standardized, it can ensure the consistency of bonding quality, which is an ideal choice for transitioning to fully automated production.

4. Double-sided lamination process

Hot Melt Extrusion Pellets can be used for edge fixation or local bonding after double-sided lamination of paper to prevent the film layer from warping or falling off. Its good wettability and permeability ensure the close bonding between the film material and the substrate, and improve the quality of the finished product. In the binding and sealing of laminated paper products, hot melt adhesive particles can provide reliable bonding support and extend the service life of the product.

5. Glazing and UV oil bonding

Suitable for the bonding needs of special surface treatment materials such as glazing paper and reflective UV coated paper. Even when facing a smooth surface, reliable bonding can be achieved to avoid debonding or poor bonding. This product has a strong surface adhesion ability, which can effectively solve the bonding problems caused by UV ink and varnish layer, and is widely used in the field of high-end printing and packaging.

6. Compatible with multiple brands of equipment

Hot Melt Extrusion Pellets are compatible with fully automatic packaging equipment from mainstream brands including Yongchuang, Dayilong, Yinghui, Dachuan, Delilong, Guqi, and Cosmin, ensuring smooth glue supply and efficient bonding on different models. Its particle morphology and physical properties have been strictly tested to meet the requirements of various equipment for key parameters such as viscosity, flow rate, melting point, etc., improving equipment compatibility and operational stability.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

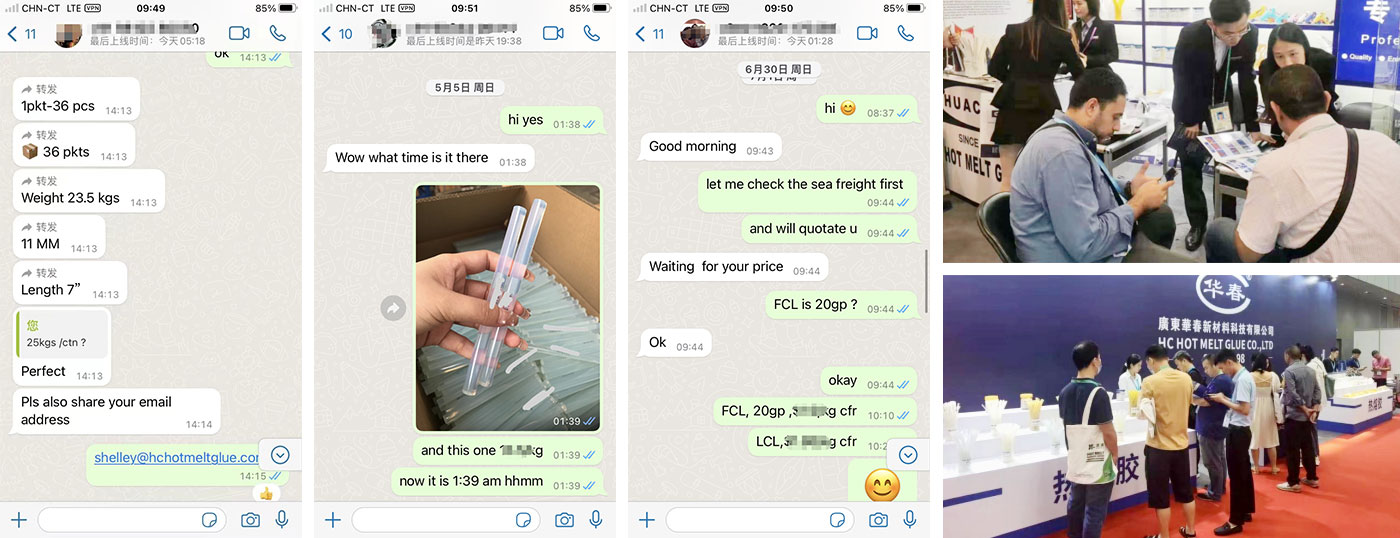

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.