Mainly Used for:

1. Fabric lamination, including foam materials such as EVA/SBR and textile materials for footwear.

2. Soft furniture lamination

3. Lamination and bonding of mattress and sofa foam

4. Memory foam adhesion

Features:

1. High initial tack and excellent machine application performance

2. Excellent adhesion effect on EVA material

3. Environmental Safety and Health: Completely free of harmful substances such as aldehydes, ketones, benzene, hydrocarbons, esters, and the like.

Suggested Operating Conditions:

1. Operating temperature should be between 150℃ and 180℃, depending on the machine, substrate, and other environmental conditions.

2. Application can be done by scraping.

3. The recommended coating thickness is 17-19 g/m² in summer and 19-21 g/m² in winter, depending on customer requirements.

Precautions:

1. Do not mix with other adhesives.

2. It is recommended to follow the principle of "first in, first out" and "add small amounts repeatedly" when adding adhesive.

3. The operating temperature is high; please wear protective equipment.

4. Keep the adhesive container covered to prevent foreign matter from entering and affecting the adhesive's performance.

5. Regularly clean the equipment to prevent residual impurities from affecting the adhesive's performance.

6. Strictly prohibit excessively high operating temperatures (<200℃), prolonged="" operation="">

This information provided is based on our knowledge and experience and only for user reference. At the same time, due to the use of different materials and changes in working conditions being beyond our control range, we solemnly suggest that the users can conduct an exhaustive experiment to use parameters in the end.

| Color | White |

| Packing | 25KG/bag |

| Curing Time | 5-10 S |

| Working Temperature | 150-180 ℃ |

| Shape | Block |

| Softening Point | 85±5°C |

| Opening Time | 15-30 S |

| Brinell Bonding(CPS) | 160℃, 2038cps |

| Brinell Bonding(CPS) | 170℃, 1650cps |

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

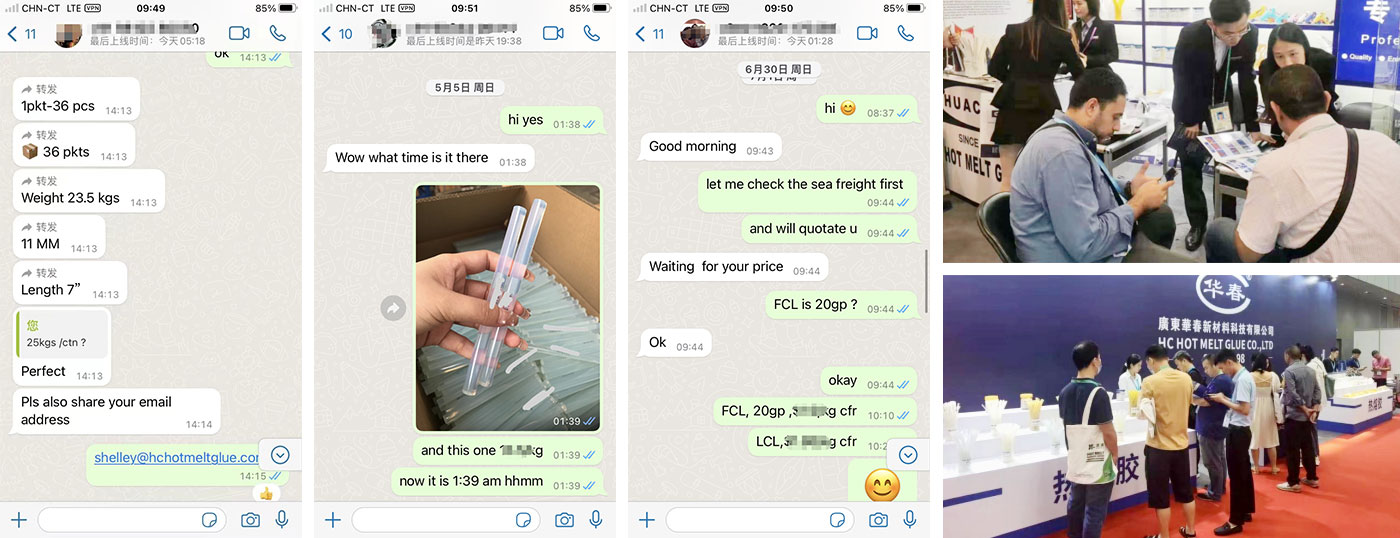

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.