Hot Glue for Wood is a hot melt adhesive specifically designed for wood bonding. It's a thermoplastic polymer material that becomes liquid when heated and rapidly solidifies upon cooling, forming a strong bond. Widely used in the woodworking industry, this glue is indispensable in wood furniture manufacturing due to its efficient bonding properties and rapid curing speed. It securely bonds wood together in a short period of time, ensuring the structural stability and durability of furniture. Its main ingredients, including polymer resins, tackifiers, and waxes, work together to ensure excellent adhesion to the wood surface while also providing flexibility and impact resistance to suit the natural characteristics of wood.

| Model | HCGGH210 |

| Viscosity (170º) | 5159 ± 200 CPS |

| Softening Time | 115 ± 5℃ |

| Open Time | 8~10S |

| Set Time | 2~3S |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

1. High Tack:

Hot Glue for Wood HCGGH210 has extremely high tack, with a viscosity of 5159 ± 200 CPS at 170°C, meaning it forms a strong bond on wood surfaces. This high tack ensures a tight bond between wood components that remains stable even under significant pressure or impact. In furniture manufacturing, high tack is crucial for ensuring product durability and structural integrity.

2. Fast Curing:

Hot Glue for Wood cures quickly, with a softening time of 115 ± 5°C, an open time of 8-10 seconds, and a curing time of 2-3 seconds. This fast curing feature significantly improves production efficiency and reduces waiting time. In wood furniture manufacturing, fast curing ensures production line continuity, increases output, and ensures consistent bonding results.

3. Environmentally Friendly and Non-Toxic:

Hot Glue for Wood HCGGH210 is made from environmentally friendly materials that meet international environmental standards and is non-toxic and harmless. During wood processing, the environmental friendliness of glue is crucial, as it directly impacts product quality and user health. Using environmentally friendly glue ensures that furniture releases no harmful substances during use, meeting modern consumer demand for environmentally friendly products.

4. High-Temperature Resistance:

Hot Glue for Wood can withstand high temperatures, with a softening point of 115 ± 5°C. This means it maintains excellent bonding properties even in high-temperature environments and resists melting or failure. In wood furniture manufacturing, this high-temperature resistance ensures that the glue's bonding is not affected by high temperatures during processing, thereby improving product quality and reliability.

5. Good Flexibility:

Hot Glue for Wood HCGGH210 exhibits excellent flexibility, allowing it to adapt to the natural characteristics of wood. Wood may expand or contract slightly due to environmental changes during use, and this flexible glue effectively cushions these changes, preventing cracks or loosening at the bonded joints. This flexibility ensures the stability and durability of furniture over long-term use.

1. Furniture Assembly:

Hot Glue for Wood plays a vital role in furniture assembly. It quickly and securely bonds furniture components together, ensuring structural stability. Whether it's a chair, table, or cabinet, Hot Glue for Wood provides reliable bonding, improving production efficiency while ensuring product quality and durability.

2. Wood Repair:

Hot Glue for Wood is also commonly used for wood repair. When cracks or damage occur in wood, Hot Glue for Wood can be used to quickly repair it, restoring its integrity and aesthetics. Its high adhesion and fast curing properties make the repair process simple and quick, restoring the wood's original strength and functionality.

3. Wood Splicing:

Hot Glue for Wood is an ideal bonding material for wood splicing. It securely joins wood pieces of different shapes and sizes together to form a complete wood panel. This splicing method not only saves material and improves wood utilization, but also ensures the structural strength and stability of the resulting spliced wood.

4. Wood Decoration:

Hot Glue for Wood can also be used for wood decoration. When creating wood carvings, wood ornaments, or wooden crafts, Hot Glue for Wood firmly adheres various decorative elements to the wood surface, ensuring a durable and aesthetically pleasing finish. Its fast curing and high adhesion make the decoration process efficient and convenient.

5. Furniture Restoration:

Hot Glue for Wood is also widely used in furniture restoration. When furniture is damaged or loose, Hot Glue for Wood can be used to quickly repair it, restoring its functionality and appearance. Its environmentally friendly, non-toxic, and high-temperature resistance make the repaired furniture safer and more durable, extending its lifespan.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

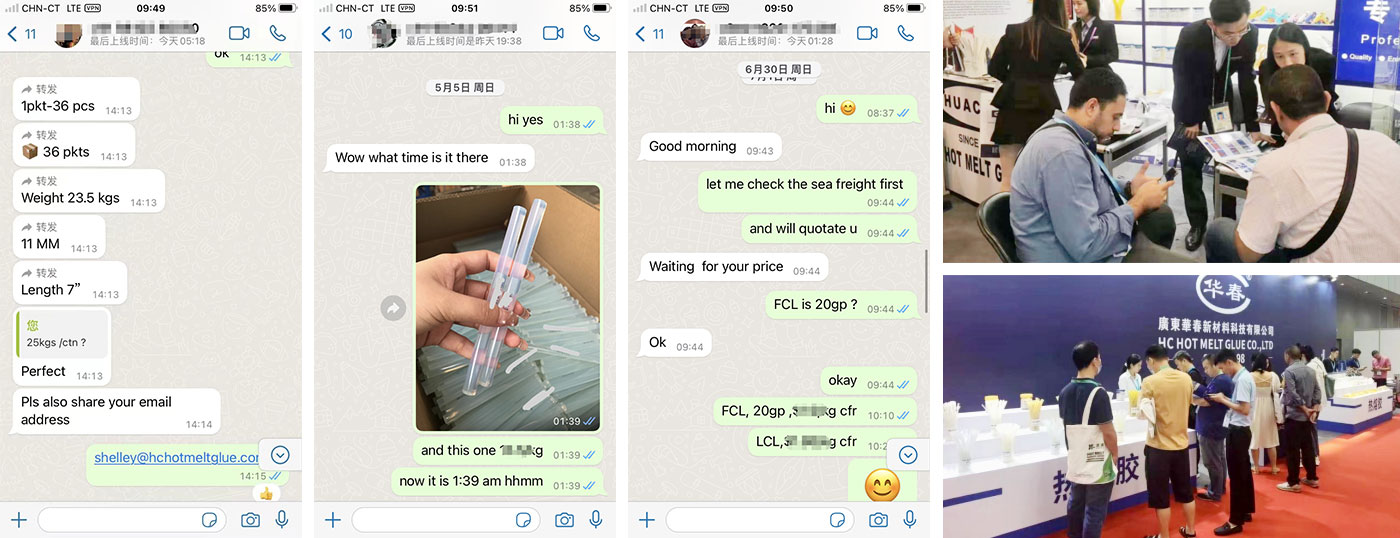

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.