Yellow Hot Glue is a thermoplastic adhesive material with ethylene-vinyl acetate copolymer (EVA) as the main component. It is named because it turns golden yellow when heated. This type of adhesive has good fluidity and wettability when heated, and quickly solidifies and forms a high-strength bonding layer after cooling. Its molecular structure contains polar groups, which enhances the adhesion to a variety of materials. It also has excellent cohesion and aging resistance. Unlike water-based or solvent-based adhesives, Yellow Hot Glue can achieve instant bonding without water evaporation or chemical reaction. It is efficient and environmentally friendly.

| Model | HCGG265 |

| Viscosity (170º) | 8300 ± 200 CPS |

| Softening Time | 78 ± 5℃ |

| Open Time | 20~40S |

| Set Time | 8~10S |

| Application Temperature | 160℃-190℃ |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

| Compay Nature | China Manufacturers Suppliers Factory |

1. High viscosity:

This product has excellent viscosity performance. It can still maintain a high consistency in the heated and molten state, ensuring that it is not easy to flow during the coating process. It is suitable for scenes that require thick coating or vertical surface bonding, and effectively improves the bonding strength and stability. The polymer chains have strong interaction forces, and can still maintain a good cohesive structure in the molten state, so that it still shows excellent anti-sagging ability at high temperatures.

2. No drawing:

Yellow Hot Glue adopts a special formula design to avoid the common drawing phenomenon of traditional hot melt adhesives, improve the operation cleanliness and use experience. It is especially suitable for automated production lines to reduce problems such as glue breaking and gun jamming, and improve equipment operation continuity and operation efficiency. By optimizing the resin ratio and molecular fluidity control, the ductility of the colloid during cooling is significantly reduced, achieving a clean and neat glue discharge effect.

3. Low temperature resistance:

Even in low temperature environments, it can maintain good flexibility and bonding performance, and will not become brittle and fail due to temperature drops. This feature makes it suitable for bonding needs under various low temperature conditions such as winter warehousing and cold chain transportation. The introduction of flexible segments and plasticizing components inside the colloid allows the material to still have sufficient free volume at low temperatures, thereby maintaining good viscoelastic properties and adhesion.

4. Stable viscosity:

The colloid can still maintain stable viscosity performance during repeated heating and cooling, without viscosity attenuation or performance fluctuations, ensuring long-term reliability and consistency, and meeting the quality control standards for large-scale industrial applications. It has strong thermal stability and excellent antioxidant properties, and can maintain its original performance in multiple melt-solidification cycles to avoid the decrease in adhesion caused by thermal aging.

5. Fast curing:

After heating and applying Yellow Hot Glue, it can be quickly cooled and cured in a short time to form a strong bonding layer, shortening the process waiting time, and is suitable for fast-paced production processes such as high-speed box sealing and automatic labeling, improving overall operating efficiency. By adjusting the crystallization speed and thermal conductivity, the colloid can quickly establish initial adhesion after leaving the coating tool, accelerating the closure and strength establishment of the bonding interface.

6. Strong adhesion:

Yellow Hot Glue has good wettability and adhesion to a variety of substrates such as paper, wood, plastic, and metal. It can achieve uniform coating and tight bonding, reduce undesirable phenomena such as degumming and bubbles, and improve the quality and aesthetics of the finished product. The colloid contains polarity-enhancing components, which improves the affinity for low surface energy materials and makes the bonding layer more compact and stable.

7. Strong anti-aging:

By adding antioxidants and UV stabilizers, the weather resistance of the colloid is significantly improved. It is not easy to yellow or brittle after long-term exposure to air. It is suitable for packaging applications that require long-term storage or outdoor use. The introduction of antioxidant factors in its molecular structure effectively inhibits free radical reactions, extends the service life of the colloid, and maintains long-term stability of the bonding performance.

8. Convenient operation:

Yellow Hot Glue adopts a standardized stick design, which is suitable for various manual glue guns and automatic glue supply systems. It is easy to use and simple to operate, which reduces the threshold for manual operation. It is especially suitable for small and medium-sized production enterprises and on-site maintenance scenarios. The rods have uniform size, which is convenient for mechanical feeding and precise feeding. They also have good pressure resistance and are not easy to break or damage during transportation and storage.

1. Electronic product packaging

Yellow Hot Glue Stick is suitable for fixing and packaging electronic components, circuit boards, power modules and other products, providing strong bonding and buffer protection. Its high viscosity and non-drawing characteristics help to accurately apply glue, prevent accidental short circuits, and ensure the safe assembly and transportation of electronic products.

2. Handicraft production

Yellow Hot Glue Stick is widely used in DIY handicrafts, model assembly, decorative picture frames and other scenes, and can be bonded to a variety of materials such as wood, cloth, and ceramics. Its quick-drying characteristics facilitate manual operation and improve creative efficiency. At the same time, it does not leave residual glue, which is convenient for later adjustment and cleaning.

3. Toy assembly

Yellow Hot Glue Stick is suitable for bonding and fixing toy components such as plastics, foams, and cloth velvet, helping to achieve rapid prototyping and strong connection. Its low temperature resistance and anti-aging properties also ensure the safety of toys in various environments, and meet the safety bonding standards for children's products.

4. Carton packaging

Yellow Hot Glue Stick is specially designed for carton sealing, corner reinforcement, pallet fixing and other links, and is suitable for high-frequency use scenarios such as e-commerce logistics and express packaging. Its high viscosity and fast curing ability significantly improve packaging efficiency and enhance the overall load-bearing and shock-proof performance of the packaging.

5. Metal bonding

Yellow Hot Glue Stick can be used for temporary fixation or auxiliary bonding between light metal parts, such as the pasting of nameplates, labels, brackets and other parts. Its excellent adhesion performance enables it to form a stable bonding layer on the metal surface, improving assembly efficiency and appearance neatness.

6. Plastic product bonding

Yellow Hot Glue Stick is suitable for bonding applications of various engineering plastics such as ABS, PP, PS, etc., and is widely used in assembly operations in industries such as home appliance housings, packaging containers, and automotive accessories. Its good wettability ensures that the bonding interface is dense and free of gaps, improving the structural stability of the finished product.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

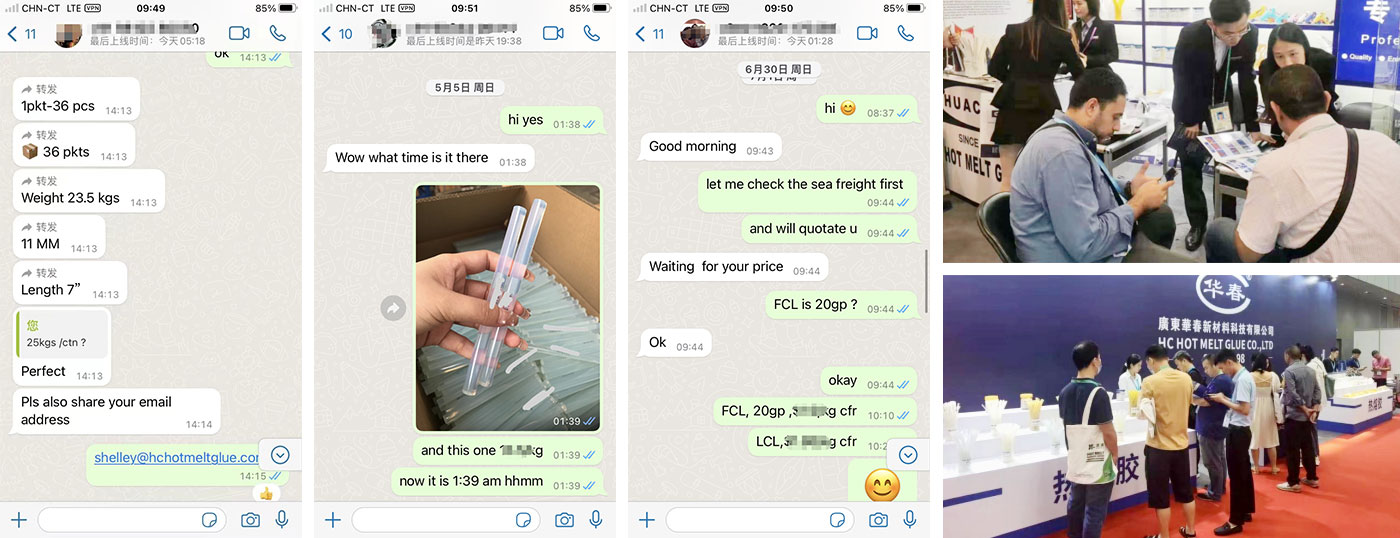

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.