Packaging Hot Melt Adhesive is an adhesive widely used in the packaging field. It is heated and melted, then applied to the surface of the adherend, and cooled and solidified to achieve bonding. This adhesive has the advantages of fast bonding, no solvent pollution, and easy operation. It is suitable for packaging bonding of various materials and can effectively improve packaging efficiency and quality. It is widely used in packaging industries such as electronics, handicrafts, and toy cartons. It is an indispensable material for modern packaging.

| Model | HCGG267 |

| Viscosity (170º) | 8971 ± 200 CPS |

| Softening Time | 77 ± 5℃ |

| Open Time | 25~35S |

| Set Time | 10-15S |

| Application Temperature | 160℃-190℃ |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

1. High viscosity:

Deep Yellow Heavy Duty Packaging Hot Melt Adhesive Sticks has a high viscosity of 8971±200 CPS (at 170℃), which is much higher than ordinary packaging hot melt adhesives. This high viscosity enables it to better fill the tiny gaps on the surface of the adherend, provide stronger adhesion, ensure the firmness of the packaging structure, and perform well even in heavy packaging or complex shape packaging, meeting high-standard packaging needs.

2. No stringing:

Packaging Hot Melt Adhesive Sticks have non-stringing characteristics and will not string during use. This is due to its unique formula and production process, which enables it to maintain a stable colloidal state during the application and curing process, avoiding problems such as uneven bonding and untidy appearance caused by stringing, improving the aesthetics and bonding efficiency of the packaging, and meeting the strict quality requirements of modern packaging.

3. Strong cold resistance:

Packaging Hot Melt Adhesive Sticks have good cold resistance and can maintain stable bonding performance in low temperature environments. Even in cold storage or transportation conditions, the colloid will not become brittle or lose its viscosity due to the decrease in temperature, ensuring that the integrity of the packaging is not affected, meeting the packaging needs of different regions and seasons, with strong adaptability and meeting the industry's high standards for packaging adhesive temperature resistance.

4. Stable viscosity:

The Packaging Hot Melt Adhesive will not lose viscosity during use. Its viscosity can remain stable for a long time after curing, and will not weaken due to the passage of time or environmental changes, ensuring that the packaging is always firm and reliable during long-term storage and transportation, effectively avoiding problems such as loose packaging and breakage caused by decreased viscosity, and providing long-term protection for packaging.

5. Fast curing:

Packaging Hot Melt Adhesive Sticks have a fast curing time of 10-15 seconds, which can complete bonding in a short time, greatly improving packaging efficiency. At the same time, its softening time of 77±5℃ and opening time of 25-35 seconds provide operators with a reasonable time window, which can not only ensure that the colloid is fully applied and bonded, but also quickly solidify and shape, meeting the requirements of modern packaging production lines for fast and efficient.

6. Wide application temperature:

The application temperature range of Deep Yellow Heavy Duty Packaging Hot Melt Adhesive Sticks is 160℃ - 190℃, and the wide temperature range makes it adaptable to different heating equipment and operating environments. Whether it is small manual packaging or large automated production lines, it can perform at its best at the right temperature, ensuring that the bonding effect is not limited by the equipment, and improving the versatility and applicability of the product.

7. Environmental protection and safety:

Packaging Hot Melt Adhesive Sticks strictly follow environmental protection standards during the production process, without the addition of harmful substances, and meet international environmental protection requirements. It does not evaporate solvents during use, will not cause pollution to operators and the environment, and is an ideal choice for green packaging, helping companies to improve their environmental image and meet the market's demand for environmentally friendly packaging materials.

8. Easy to operate:

This Packaging Hot Melt Adhesive is designed in a stick shape, which is easy to operate with a hot melt glue gun. It has a uniform texture and good fluidity after heating. It can be easily applied to the surface of various materials. It is simple and convenient to operate, and can be used without complex training. It is suitable for manual packaging scenarios and improves the convenience and flexibility of packaging work.

1. Electronic product packaging:

In electronic product packaging, Deep Yellow Heavy Duty Packaging Hot Melt Adhesive Sticks can be used to fix electronic components, bond packaging boxes, etc. Its high viscosity and fast curing characteristics can ensure that the packaging of electronic products will not loosen during transportation. At the same time, the no-wire and environmentally friendly characteristics ensure that the packaging appearance is neat and tidy, meeting the strict requirements of electronic products for packaging quality.

2. Handicraft packaging:

Handicraft packaging usually requires a fine bonding process. Packaging Hot Melt Adhesive is suitable for handicraft packaging box bonding, decorative fixing, etc. Its cold resistance and stable viscosity characteristics can ensure the packaging integrity of handicrafts in different environments. At the same time, its easy operation makes it convenient for craftsmen to carry out manual packaging and improve packaging efficiency and quality.

3. Toy carton packaging:

Toy carton packaging needs to withstand a certain weight and bumps during transportation. The high viscosity and cold resistance of Deep Yellow Heavy Duty Packaging Hot Melt Adhesive Sticks can ensure that cartons remain firm under low temperature or heavy load conditions. Its fast curing and no-wire pulling characteristics improve packaging efficiency and make toy carton packaging more beautiful and durable.

4. Metal packaging:

For metal packaging, such as metal cans, metal accessories, etc., Packaging Hot Melt Adhesive can provide good adhesion. Its high viscosity and wide application temperature range enable it to adapt to the special requirements of metal surfaces, ensure the firmness and stability of metal packaging in various environments, and meet the high standards of metal packaging for adhesives.

5. Plastic packaging:

In plastic packaging, such as plastic boxes, plastic bottles, etc., Packaging Hot Melt Adhesive Sticks can form a good bond with the plastic surface. Its no-wire pulling and fast curing characteristics ensure that plastic packaging can be quickly bonded on the production line. At the same time, its cold resistance and stable viscosity characteristics ensure the integrity of plastic packaging during storage and transportation, and improve packaging quality.

6. Carton packaging:

Carton packaging is one of the most common packaging forms. Packaging Hot Melt Adhesive can be used for bonding and sealing cartons. Its high viscosity and fast curing characteristics can ensure that the carton is firmly formed in a short time. At the same time, its environmentally friendly and safe characteristics meet the environmental protection requirements of carton packaging, providing a reliable and efficient bonding solution for carton packaging.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

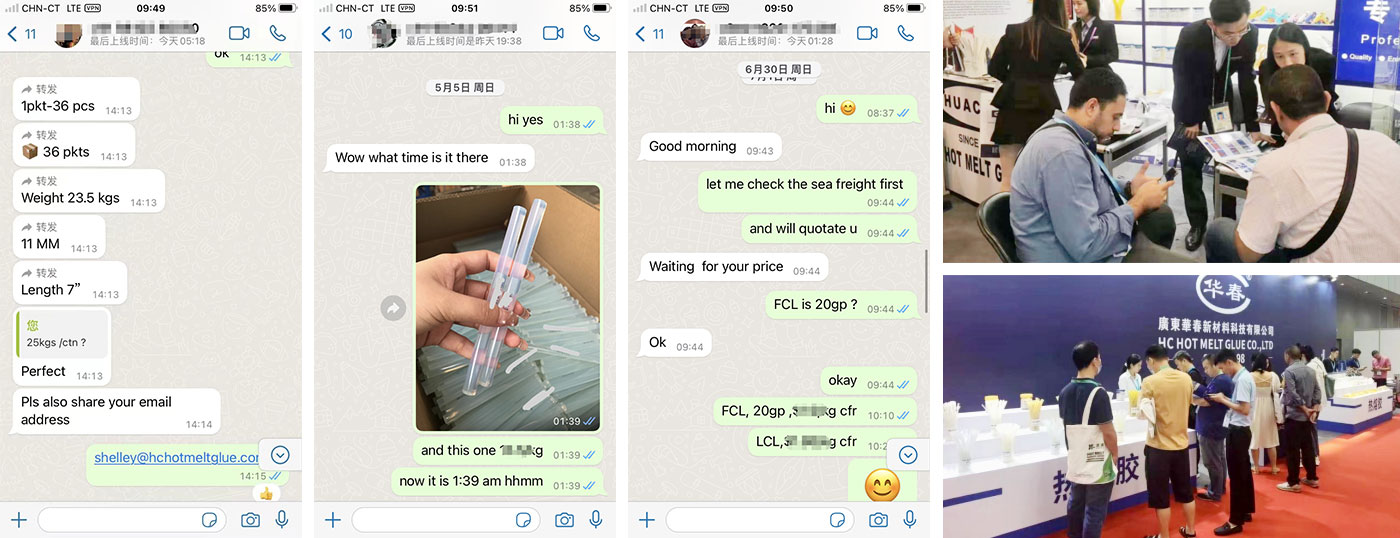

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.