Hot Glue for Electronics is an adhesive material designed specifically for the electronics industry. It plays a key role in the manufacturing, repair, and assembly of electronic equipment. The delicate internal structures of electronic devices place extremely high demands on adhesive performance. hot melt adhesives for electronics must possess excellent insulation properties to ensure the proper functioning of electronic components and avoid faults such as short circuits. At the same time, they must withstand the heat generated by electronic devices during use and maintain stable bonding performance. Furthermore, hot melt adhesives for electronics must possess a certain degree of flexibility to accommodate slight deformations that may occur during use and prevent cracking at the bonded areas. With the trend towards thinner and lighter electronic products, hot melt adhesives for electronics must also meet the requirements of low odor and low volatility to ensure a stable internal environment and extend the life of the electronic equipment.

| Model | HCGG201 |

| Viscosity (170º) | 11500 ± 200 CPS |

| Softening Time | 78 ± 5℃ |

| Open Time | 18~25S |

| Set Time | 2~5S |

| Application Temperature | 160℃-190℃ |

| Place of Origin | China |

| Item | Hot Melt Adhesive |

| Usage | Electronic, Handcraft, Toy, Carton packing, Metal, Plastic, Box |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Availalbe |

| Transportation | Availalbe |

| Payment Method | TT |

| Terms of Trade | EXW, FOB, CIF, DDP |

| Supply Capacity | 500 Tons/Month |

| Certification | CE, MSDS, ROHS, SGS |

| Compay Nature | China Manufacturers Suppliers Factory |

1. High Viscosity:

This 7mm x 11mm Clear Hot Glue for Electronics boasts a viscosity of 11,500 ± 200 CPS (at 170°C), significantly higher than typical hot melt adhesives. This ensures a strong bond in complex electronic device structures, such as between circuit boards and housings, effectively preventing component loosening and meeting the electronics industry's high bond strength requirements.

2. Moderate Softening Time:

Its softening time is 78 ± 5°C. During electronic device assembly, this moderate softening time allows operators ample time for precise positioning and adjustment, ensuring accurate bonding. It also prevents excessive heat buildup and damage to electronic components caused by prolonged softening time, ensuring the Hot Glue for Electronics' bonding performance and component safety.

3. Reasonable Open Time:

An open time of 18-25 seconds provides ample time for bonding operations during electronic device assembly. Operators can complete the splicing and initial fixation of the bonded components within this time, ensuring a smooth and secure bond. This avoids inadequate bonding due to a short open time or loss of adhesive strength due to an extended open time, which could affect the final bonding performance of Hot Glue for Electronics.

4. Fast Curing:

With a curing time of 2-5 seconds, 7mm/11mm Clear Hot Glue for Electronics cures quickly on electronic equipment production lines, significantly improving production efficiency. During the rapid assembly of electronic products, this fast curing feature reduces waiting time and speeds up production. It also ensures that the bond reaches sufficient strength quickly, safeguarding the structural stability of electronic devices and meeting the electronics industry's dual demands for production efficiency and product quality.

5. Suitable Application Temperature:

With an application temperature range of 160°C-190°C, it adapts to the diverse heating requirements of electronic equipment production. Whether it's surface mounting electronic components or molding electronic device housings, this Hot Glue for Electronics delivers optimal bonding performance at optimal temperatures, ensuring the bond is unaffected by temperature fluctuations, providing reliable bonding for electronic device manufacturing.

6. Transparent and Beautiful:

The transparency of the 7mm/11mm Clear Hot Glue for Electronics offers unique advantages in electronic device design. For electronic products with demanding aesthetics, such as smartphones and tablets, transparent hot melt adhesive will not detract from the overall aesthetics. It also facilitates inspection and repair of bonded areas, ensuring both reliability and aesthetics are maintained.

1. Attaching Electronic Components:

During the assembly of electronic devices, 7mm/11mm Clear Hot Glue for Electronics can be used to secure various electronic components, such as chips, capacitors, and resistors. Its high viscosity and fast curing properties ensure a stable bond between components and the circuit board, preventing them from falling out due to vibration or impact, thereby ensuring the proper operation of the electronic device. Its transparency also facilitates inspection and inspection of the bonding process.

2. Bonding Circuit Boards to Housings:

The housings of electronic devices often need to be bonded to the circuit boards to form a complete structure. Hot Glue for Electronics' high viscosity and moderate softening time allow it to effectively bond the circuit boards to the housing, ensuring a tight connection between the two. During use, this bonding method effectively prevents dust and moisture from entering the device, enhancing its reliability and service life.

3. Sealing Electronic Devices:

Hot Glue for Electronics can be used to seal certain electronic devices, such as waterproof watches and cameras. Its excellent bonding properties and transparency ensure the seals are secure and aesthetically pleasing. It also meets the requirements of electronic devices for various environments, such as waterproofing and dustproofing, providing reliable sealing for electronic devices.

4. Electronic Equipment Repair:

Hot Glue also plays a vital role in electronic equipment repairs. When a damaged component needs to be replaced, this hot melt adhesive can be used to bond and secure the new component. Its fast curing and high viscosity ensure the repaired electronic device can be quickly restored to normal operation, while also ensuring the secureness and stability of the repaired component, improving the repair quality and service life of the electronic device.

5. Electronic Equipment Labeling:

Electronic device casings often feature markings such as brand logos and product model numbers. Hot Glue for Electronics can be used to secure these markings. Its transparency does not affect the aesthetics of the markings. Its high viscosity and fast curing properties ensure a secure bond, preventing the markings from falling off or becoming damaged during use, thereby protecting the integrity of the brand image and product information of the electronic device.

At our factory, every shipment reflects the precision, professionalism, and dedication we bring to our production process. With a state-of-the-art facility and a highly skilled team, we ensure that each order is meticulously inspected and carefully packed to meet international quality standards.

With advanced testing equipment and highly trained personnel, we rigorously examine materials and products for durability, performance, and compliance with industry standards. Our commitment to precision and quality control is evident in every step of our testing process, from material selection to final inspection.

Our factory boasts a highly efficient and modern production environment dedicated to manufacturing top-quality glue sticks and granules. Equipped with advanced machinery and operated by experienced technicians, we ensure that every step of the production process is meticulously controlled to meet international standards.

The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.

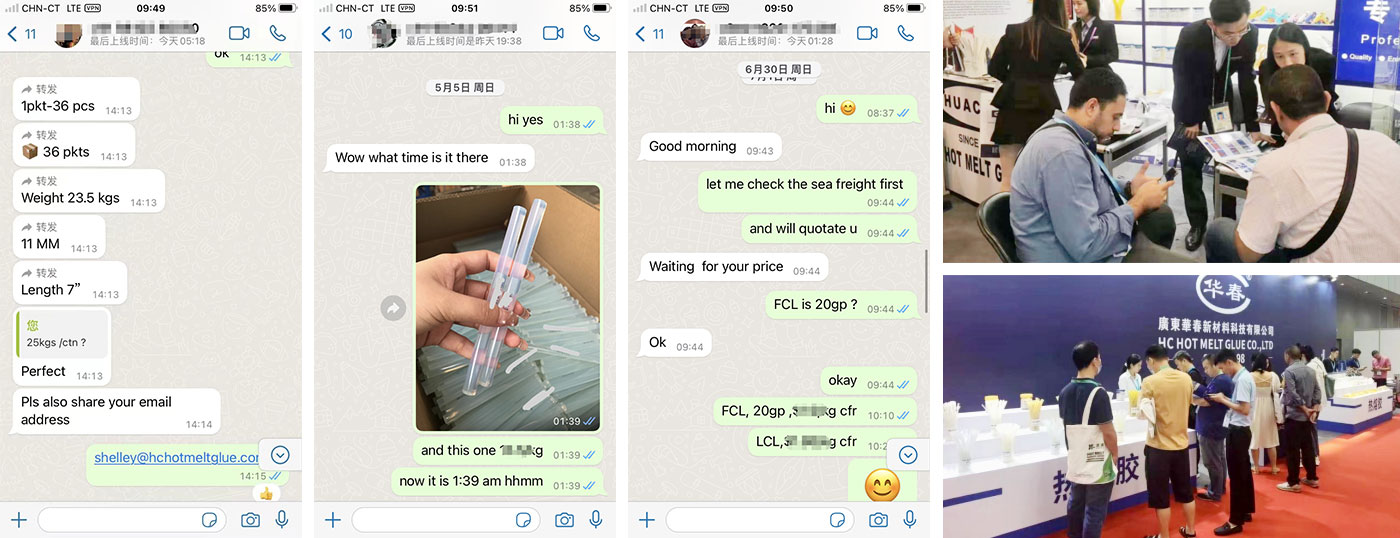

Whether through instant messaging platforms or face-to-face interactions at international trade shows, our team is dedicated to addressing all client inquiries promptly and accurately. Our participation in global exhibitions not only allows us to showcase our high-quality glue sticks and granules but also provides opportunities to connect with customers directly, understanding their needs and offering tailored solutions.

Jiangmen Huachun High tech Materials Co., Ltd. Was founded in 1998, it develops, produces and markets environmentally friendly hot melt adhesives. With abundant capital, complete technical force and advanced production capacity, the products are mainly made of high-quality raw materials and advanced technology at home and abroad, and we also have strict testing procedures to provide customers with high-quality and stable adhesives.

The product quality is excellent, which has been praised by customers repeatedly and enjoys a high reputation. The environment-friendly hot melt adhesives are used in various automatic production lines, such as carton sealing, cigarette stick bonding, color box packaging, wood edge sealing, book binding, print lamination, the air filter, the shoe industry and sanitary products.